Isostatic pressing in EV solid-state batteries – Tech News 2303

Preface

Isostatic pressing in EV solid-state batteries

Commercializing EV solid-state batteries is crucial due to their faster charging, longer lifespan, and safer operation compared to conventional batteries.

Brief of EV solid-state batteries

According to Oak Ridge National Laboratory (ORNL) of the U.S. Department of Energy, battery researchers suggest that the EV solid-state battery industry should focus on isostatic pressing technology in order to promote the commercialization of next-generation batteries based on promising test results.

Scaling up production of EV solid-state batteries is a goal for electric vehicle manufacturers because these batteries have the potential to charge faster, last longer, and operate more safely than current lithium-ion batteries available in the market. Therefore, it is crucial to achieve large-scale manufacturing of solid-state batteries as well.

“By effectively addressing these challenges we can surpass current battery technologies and enable energy-dense solid-state batteries to meet rapidly growing demands in portable electronic devices, grid storage systems, electric vehicles as well as aviation applications.

Working principle of Isostatic pressing

The working principle of isostatic pressure is based on Pascal’s law, which states that the pressure exerted by a liquid or gas in a closed container can be transmitted equally in all directions. This process utilizes liquids and gases like water, oil, or argon within the machine to apply consistent pressure on battery components, resulting in highly uniform materials.

During the charging or discharging of a battery, ions pass through the electrolyte between positive and negative electrodes composed of thin metal layers. In lithium-ion batteries used for devices such as smartphones and electric cars, the electrolyte is a liquid that allows easy ion movement. However, if there is damage to the separation between battery layers, this liquid may leak out or ignite.

Isostatic pressure technology enables the production of uniform solid-state electrolyte thin layers to maintain high contact between layers for smooth ion movement. This method can be applied to various battery compositions under different temperatures and pressures.

Research results also demonstrate that using flexible electrolyte materials with isostatic pressure technology has been highly successful at low temperatures. Soft electrolyte materials are easier to process and possess crystal structures suitable for ion movement compared to previous methods where extreme conditions such as very high temperatures or room temperature were required but not anything in-between.

EV solid-state batteries applications

All these materials have their unique advantages, and researchers hope to harness them. That’s why the importance of isostatic pressing can be found at temperatures ranging from room temperature to several thousand degrees Fahrenheit, enabling the utilization of a wide range of materials including polymers and oxides. This versatility is crucial for maintaining consistency in the manufacturing processes of various EV solid-state battery designs and materials currently under development.

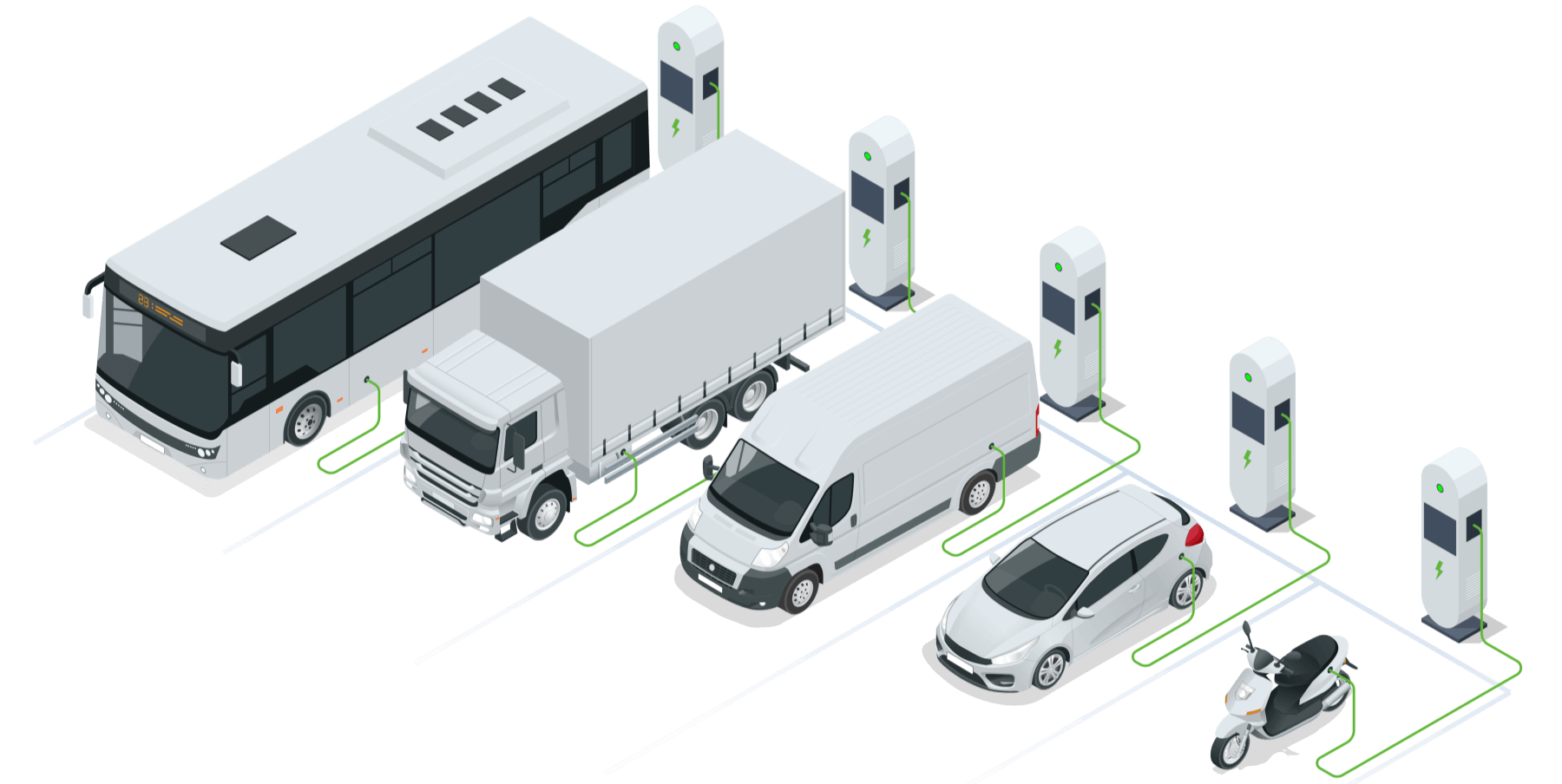

Several leading EV companies have announced their plans to sell electric vehicles equipped with solid-state batteries in the next few years. Undoubtedly, all EV solid-state batteries are capable of long-distance travel, but if the technology of isostatic pressure can be scaled up, it will provide a practical method for assembling battery layers.

By applying isostatic pressure, the three battery layers can be manufactured as a single dense system instead of being created separately before their connection. Effectively addressing this challenge will enable energy-dense solid-state batteries to meet the emerging demands of portable electronic devices, grid storage, electric vehicles, and even aerospace applications, thus driving today’s battery technology forward into the next few decades.

0 Comments